Why Treat When You Can Purify?

Purifics delivers fully integrated water purification technologies built on over 30 years of proven results in municipal and industrial applications. Our systems combine Cuf® and chemical-free AOP+ (Photo-Cat®) with full automation to provide complete, reliable, and sustainable water purification, including ZLD, PFAS removal, membrane testing, and more, all supported by a strong foundation of innovation and 30+ patents.

Continuous Ultra-Filtration

Advanced multi-contaminant removal in a single platform, no pre-treatment required and with full Zero Liquid Discharge (ZLD) capability.

Photo-Cat

A chemical-free, photocatalytic Advanced Oxidation Process (AOP+) delivering the

highest oxidation potential in the industry.

Purifics developed and patented the first marker-based Direct Integrity Test (DIT) designed to meet LT2ESWTR compliance requirements. This breakthrough replaces traditional pressure decay (PD) methods still widely used across the membrane industry, offering significantly higher sensitivity. DIT eliminates reduced Log Removal Value (LRV) certifications, ensuring full regulatory compliance without compromise.

Direct & Indirect Integrity Testing (DIT)

Marker Method Direct Integrity Test (DIT)

Turbidity Indirect Integrity Verification

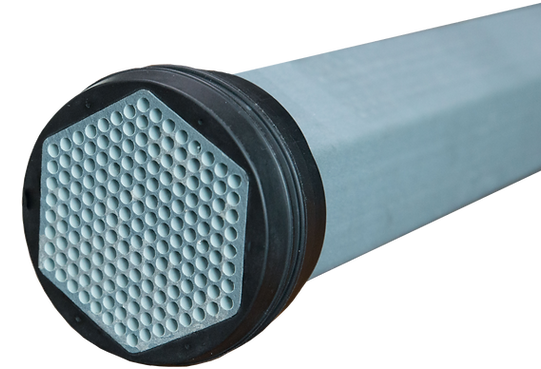

Purifics’ systems feature an advanced 100% silicon carbide (SiC) ceramic membrane as an integral part of the purification process. While it is a powerful filtration step, the membrane is just one component of our integrated platform, which combines additional proprietary technologies to completely remove and destroy a wide range of contaminants, all in a single, compact unit.

Key Benefits Include:

-

No end-of-life membrane – 25+ years design life

-

Most hydrophilic membrane – Superior water flow rates from 250 GFD to 500 GFD

-

Lower operational costs – Delivering more water for less energy

-

Reduced maintenance – Resistant to permanent fouling

-

Extreme durability – Handles harsh conditions (extreme weather and chemicals) effortlessly

-

Sustainable solution – Long-lasting and environmentally friendly

SiC Ceramic Membrane

A Key Part of a Bigger Solution